Some Known Details About Sheroz Earthworks

Some Known Details About Sheroz Earthworks

Blog Article

Sheroz Earthworks Can Be Fun For Everyone

Table of ContentsThe Sheroz Earthworks StatementsThe Definitive Guide for Sheroz EarthworksThe Single Strategy To Use For Sheroz EarthworksThe 10-Second Trick For Sheroz Earthworks6 Easy Facts About Sheroz Earthworks Described

For any kind of earthwork service provider, it is essential to carry out work with high quality, accuracy, and on time. Making use of equipment control in job devices allows optimizing the various phases in the earthwork process, from planning to the maintenance stage - trimble tripod parts. The equipment control system helps the machine operator in achieving the target airplane promptly and quickly

The equipment control system overviews the operator with centimeter precision. With Xsite PRO 3D, you'll constantly understand specifically just how much to cut or fill up. Your local Xsite technological support can guide you and aid with any type of issues without seeing the website. Remote support saves time and cash, as it reduces downtime in jobsites.

The 6-Minute Rule for Sheroz Earthworks

Extra training and directions are always readily available over remote assistance when needed. The earthmoving industry has actually utilized our field-proven solutions because the early 1990s. Our system's components are meticulously made to withstand the rough conditions of building and construction websites. Comparison of the very same project implemented utilizing maker control versus the conventional method exposes that, generally, the standard technique calls for 50% more time to accomplish the same job as the technology-assisted method. https://www.kickstarter.com/profile/sherozau/about.

Go into the Xsite machine control system; it's here to supply you with a significant advantage when working with earthmoving machinery. Discover how Xsite Device Control can enhance your efficiency and guarantee work safety! Xsite Maker Control systems can be mounted to any kind of excavator from mini excavators to huge mining excavators.

Exactly how does equipment control job? In 2D systems, the equipment is furnished with adjusted disposition sensing units. These sensors are placed on the pre-determined parts of the machine in excavators the sensing unit are generally placed to the frame, boom (or booms), miner arm and to the fast coupler - trimble parts. By utilizing the information obtained from these sensors the system can compute the precise placement of the excavators pail idea in importance to a referral point.

The system is very easy to find out the fundamentals can be educated in under one hour of training. Just how does the remote support job? A cordless web connection makes it possible to develop a remote connection between the equipment control system and the solution.

All About Sheroz Earthworks

Xsite Equipment Control systems support open conventional data styles, making it possible for smooth information flow from one system to an additional. Depending on your selection of system (with or without placing, i.e., 2D or 3D), your device is outfitted with inclination sensing units, a controller unit, and a display/operating panel.

Several equipment and software solutions exist to aid figure out a device's present position on the planet and contrast it with a wanted layout surfaceand building drivers can do more to leverage the benefits. Maker control is using various placing sensing units and a display to provide the operator with a recommendation between the setting of the pail or blade and the target grade.

Depending upon the setup, maker control systems can supply the driver with an easy visual overview to pail or blade placement, or can instantly relocate the blade to grade by talking with the machine's hydraulics - https://www.mixcloud.com/sherozau1/. There are maker control systems readily available for practically any type of equipment: graders, dozers, excavators, soil and asphalt compactors, scrapes, leaners, milling devices, and pavers

Sheroz Earthworks Things To Know Before You Get This

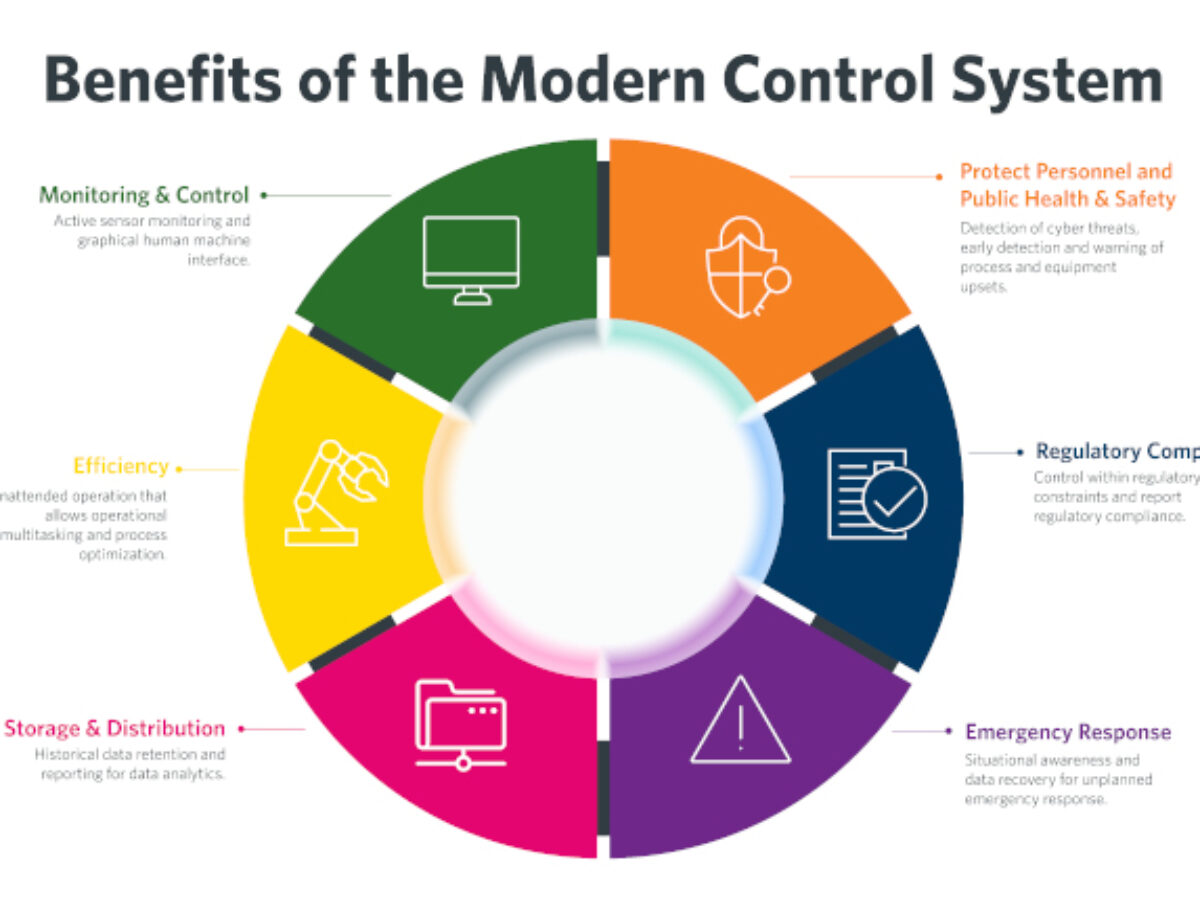

Some benefits include lowered rework, enhanced task effectiveness, and reduced evaluating expenses. Machine control can also assist increase performance and reduce total expenses. This technology is transforming the method the building and construction market works. Building equipment without equipment control will certainly become a distant memory and the advantages got from it will be many.

Trimble machine control systems supply a myriad of advantages to anybody that utilizes earthwork machinery and, at EarthCalc, we can give you with 3D data for your maker control-enable equipment. Not exactly sure if maker control deserves the cost? Consider the complying with reasons you need to consider this option.

Making use of GPS aligned with your 3D style data, these systems essentially guarantee that you will remove or place the correct quantity of material at the building site. On many building and construction sites, rework is a common and frustrating reality, yet with Trimble equipment control, you can eliminate the requirement for rework.

Some Of Sheroz Earthworks

Commonly, with Trimble equipment control, you can eliminate excess tools at a certain work website. A job that could have called for the usage of 3 or 4 items of excavating tools currently might need just 2 pieces of devices to achieve the exact same task in much less time. This enables you to move your tools to an additional work site and manage multiple jobs read more at once.

Report this page